Quality Control and Metrology: Precision at Every Stage of Production

Quality control and metrology ensure precision at every stage of production, guaranteeing efficient, reliable, and standards-compliant electric motors. 05-05-2025

Ensuring high standards in electric motor manufacturing means monitoring every phase of the process with the utmost attention. Every component, from the stator to the rotor, must meet strict tolerance requirements to ensure efficiency, durability, and optimal performance.

The quality of an electric motor depends not only on the materials used but, crucially, on the ability to control every detail during manufacturing.

Quality control and metrology play a fundamental role in identifying any deviations from design specifications. Through the use of advanced measuring instruments and rigorous procedures, the conformity of each part can be verified, preventing defects and ensuring the highest reliability of the final product.

Investing in precision technologies not only improves product quality but also optimizes costs and reduces waste, delivering increasingly high-performance and competitive solutions.

The Importance of Quality Control in Production

Quality control is not just a mandatory step, but a strategic element to reduce defects, enhance performance, and optimize production processes.

Every phase of manufacturing, from material selection to final assembly, must undergo rigorous inspections to detect any anomalies and correct them promptly.

For instance, during the production of stators and rotors for electric motors, dimensional and magnetic inspections are performed to ensure compliance with both geometric and electromagnetic tolerances. This ensures that each component integrates perfectly within the system, minimizing energy losses and improving motor efficiency.

Advanced Technologies for Precise Measurements

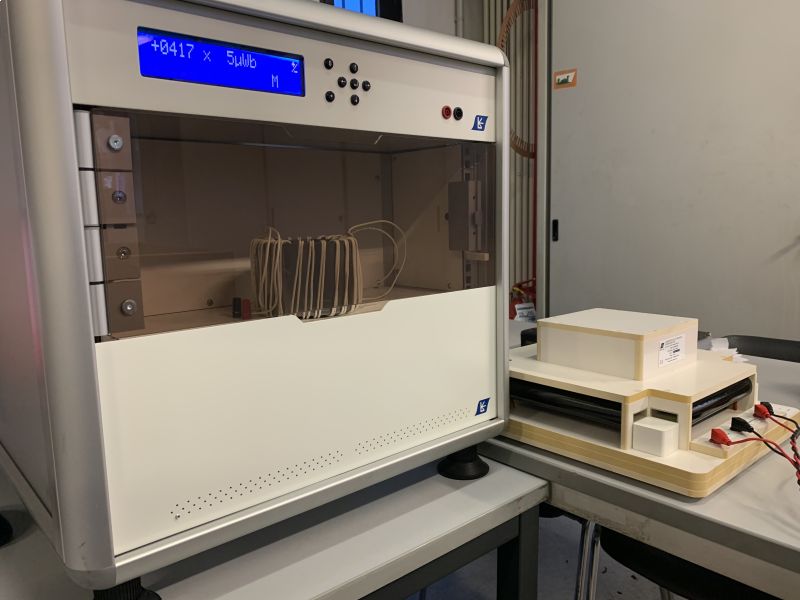

To ensure accurate quality control, it is essential to employ cutting-edge measuring technologies. In our metrology department, we utilize the latest generation of equipment to precisely verify every detail of the manufactured components.

• Coordinate Measuring Machines (CMMs): Allow the highly precise measurement of the geometric tolerances of silicon steel laminations, ensuring each part meets design specifications.

• Optical Metrology Systems: Enable the analysis of microscopic details, detecting any imperfections that could compromise motor performance.

• Magnetic Characterization Instruments: Used to test the electromagnetic properties of materials and stators, ensuring maximum energy efficiency.

The integration of these technologies enables precise and repeatable inspections, reducing the risk of defects and enhancing the reliability of the final product.

Laser Marking: Traceability and Safety

Another critical aspect of quality control is product traceability. Through laser marking, each stator and rotor is coded to ensure full traceability of the production batch.

This system allows for the monitoring of every component, ensuring quick interventions when necessary and providing customers with maximum transparency regarding product quality.

A Continuous Improvement Process

Quality control is not limited to product verification but is part of a broader continuous improvement approach.

Each customer report or feedback is carefully analyzed to identify possible optimizations in production processes.

Additionally, constant investment in new technologies and technical training allows us to refine control methodologies continuously, ensuring consistent and competitive quality over time.

Precision, reliability, and innovation: quality control and metrology are essential elements for ensuring efficient and high-performing electric motors.

Through the use of advanced technologies, accurate measurements, and rigorous process monitoring, it is possible to deliver products that meet the highest industry standards.

For industries aiming for excellence, investing in quality is always the winning choice