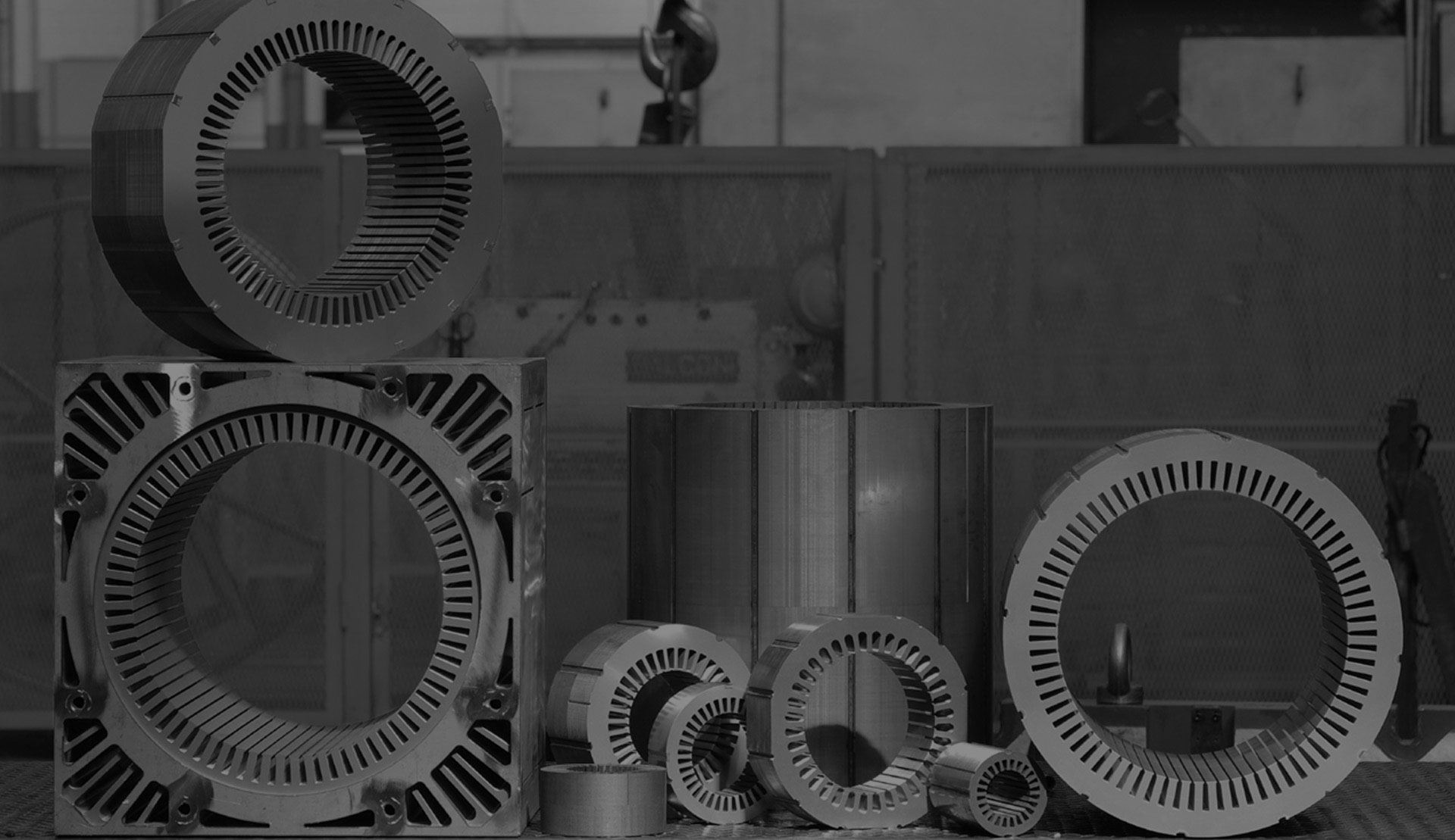

VMF – Manufacturing stators and rotors for electric motors

Born and based in Milan since the 1980s, VMF is one of the leading producers of stators and rotors for electric engines as well as being experts in the stamping and packing of silicon steel laminations.

We are a flexible and customer-oriented business; over the last 40 years we have continued to improve our production methods by introducing machinery and production lines that meet the diverse demands of the rotor and stator core industry: from steel coils and cleated or welded stators to aluminum or alloy die-casted rotors, we’ve got it covered.

VMF: Leading the future of Europe’s electrical industry by putting our clients first.

VMF’s strengths

VMF is a client-focused company at heart. With our flexible and high level production capabilities, we’re able to offer fast and direct responses to our clients.

We think it’s important to be as close as possible to each of our clients; our focus is on improving our service and quality throughout the clients’ journey, from order entry all the way up to shipment, focusing also on client aftercare.

MISSION

CUSTOMER SATISFACTION

FLEXIBILITY

Civil engineering uses

Industrial uses

Engineering uses

VMF in numbers

Every month, VMF transforms more than 2.000 tonnes of silicon steel into stators and rotors. We’re able to produce cores with different lengths, poles and die-casting Shorting rings to IEC standards form MEC size 71 up to 355, allowing us to offer one of the most complete range of products on the market. With our industry know-how, we’re also able to fulfill custom projects to the highest of standards.

As of 2022, we have 160 employees and in 2021 reached €30 millions of turnover, with 20.000 tons of steel transformed each year.

VMF’s history

VMF’s products

Civil engineering uses

• Electrical tools

• Cranes

• Power generators

• Automatic opening devices

• Excavators/tractors

• Air conditioning and ventilation

• Elevators

Renewable energy sources

• Wind turbine power generators

Industrial uses

• Industrial machines

• Forklifts

• Industrial cranes

• Industrial cleaning machines

• Industrial automation solutions

• Ventilation systems

Engineering uses

• Gearbox motors

• Brushless/permanent magnet motors

• Flameproof motors

• Waterproof pumps

• Marine electric motors

• Electrical service devices

• Linear motors

• Electric traction motors